Danh mục Mẫu Sơn

- THIẾT BỊ KIỂM TRA MỰC INK

- THIẾT BỊ CẤP CAO HÃNG TESTONE

- Kiểm Tra Độ Cứng Viết Chì Tự Động

- Máy Kéo Sơn Tự Động

- Kiểm Tra Độ Bong Tróc Sơn CUPPING

- Kiểm Tra Độ Va Đập Chuẩn DUPONT

- Cốc Đo Độ Nhớt

- Thiết bị máy Mixing Roll Machine TO-270 hãng testone

- Thiết bị máy kiểm tra độ bền kéo tensile strength của thép , vải , nhựa và các loại vật liệu khác hãng TESTONE model UNITEST M1 , model UNITEST MD , model TO-104-30 TO-104-50 TO-104-100 TO-104-200 TO-102-50 TO-102-10

- Thiết bị buồng kiểm tra chất lượng , độ bền sản phẫm mode TO-DT-20 hãng Testone

- thiết bị tủ phun muối Salt Water Spray Test Chamber Model TO-SST hãng TestOne

- THIẾT BỊ NGÀNH SƠN

- Thiết Bị Ngành Lớp Phủ

- Kiểm Tra Độ Bền Của Sơn DJH Hàn Quốc

- Thiết Bị Đo Độ Dày Lớp Phủ

- Máy Đo Độ Nhớt Sơn

- Thiết bị kéo sơn RDS

- Thiết Bị Kiểm Tra Độ Bền Sơn MEK SCRUB TESTER

- Thiết Bị Hãng INFICON Việt Nam

- Thiết Bị Đo Hàm Lượng Carbon

- Máy Đo Độ Nhớt KU Hãng LAMY/ Hãng BROOKFIELD

- Thiết bị kiểm tra độ dày sơn cao cấp ngành tôn mạ màu hãng DJH KOREA model FTS-DJH

- Máy chà búa MEK DJH

- Thiết bị máy khuấy sơn phòng thí nghiệm model Evo 0.5 Evo 0.1 Evo 1 hãng P-General

- Giấy kéo sơn hãng LENETA Việt Nam

- Thiết bị Máy đo nhiệt độ tối thiểu hình thành màng sơn MFFT 90 (Minimum Film Forming Temperature Instrument)

- Thiết bị đo độ dày , hàm lượng lớp phủ chrome+3 , chrome+6 Model 2501XBT hãng CIANFLONE USA

- Thiết bị đo hàm lượng chrome model NEX QC

- Thiết Bị Kiểm Tra Độ Mài Mòn Model TABER 5135 5155

- Thiết bị kiểm tra độ bám dính sơn 180 độ MODEL TBEND ASTMD4145

- Thiết bị máy kiểm tra độ bền chà rửa Automatic Washability Test model NEURTEK/5000AB

- Thiết bị kiểm tra độ lão hóa thời tiết bằng tia QUV model QUV/SPRAY hãng Q LAP

- thiết bị máy so sánh màu quang phổ các hãng BYK ERICHSEN SHEEN TQC XRITE DATACOLOR NEURTEK

- Thiết bị máy đo độ dày sơn trên nền betong chuyên dụng các công trình Model DEF200C3

- Thiết bị máy lắc rung giành cho gốm sứ, sản phẩm hóa học, mỹ phẩm, thực phẩm, khoáng sản, dược phẩm, bột màu, nhựa, sơn tĩnh điện, cao su, mực, bột giặt model Air Jet Sieving Machine AS 200 jet - RE

- Thiết bị máy đo độ nhớt sơn nước KU2 KU3 hãng Brookfield hãng Lamy ngành sơn nước mực in bao bì gỗ các loại sơn

- Thiết bị so sánh màu model Spectro 1000 Spectrophotometer HÃNG DATACOLOR

- Thiết bị kiểm tra độ Gel time của sơn bột tĩnh điện, hạt nhựa hãng Coesfeld Materialtest model Geltest GT 16 16/20 GT 20 GT 100 GT 150

- Máy đo Ph cầm tay hãng Horiba model PH210 PH220

- THIẾT BỊ KIỂM TRA NHIỆT ĐỘ TRONG LÒ VÀ VẬT LIỆU HÃNG PHOENIXTM

- THIẾT BỊ HÃNG NEURTEK VIỆT NAM

- Thiết bị kiểm tra độ Gel time của sơn bột tĩnh điện, hạt nhựa hãng Lamy model Gel Timer GT300 PLUS and GT300 PRODIG

- MÁY ĐO ĐỘ CHÀ XƯỚT TÔN MÀU MODEL 249 Scratch Hardness Tester LINEARTESTER 249

- hãng DJH Việt Nam, đại lí DJH Việt Nam

- Thiết bị kiểm tra độ va đập màng sơn chuẩn ASTM D2794 / ISO-1 / ISO-2 hãng Neurtek Việt Nam

- Thiết bị kiểm tra độ cứng màng sơn bằng con lắc Persoz & Konig Pendulum Hardness Tester hãng Neurtek Việt Nam

- thiết bị đo độ dày màng sơn hãng Neurtek

- Thiết bị kiểm tra thời gian khô của các loại sơn model Drying Time Recorder hãng Neurtek

- Thiết bị kiểm tra độ mài mòn của cao su nhựa thép betong gỗ H18 H22 CS-10 S-35 hãng TABER NEURTEK INSTRUMENTS

- Tủ phun muối kiểm tra độ ăn mòn , lão hóa của sản phẩm model SC500NEURTEK và model SC1000NEURTEK hãng NEURTEK

- Thiết bị máy kiểm tra độ bóng 3 góc model: RHO-NK206085(Tri gloss meter NK 20/60/85º)

- Thiết bị tủ so sánh màu JUST 3 color matching booth (D65/A/TL-84) hãng Neurtek Instruments

- Thiết bị kiểm tra độ bám dính của sơn model NK2000 hãng Neurtek Instruments

- Dụng cụ cắt mẫu tôn thử nghiệm quá trình phun muối model Sikkens NK3000 Scratch Tool hãng Neurtek Instruments

- Giấy nhiệt, giấy dán nhiệt thermax, thermal, RsPro

- THIẾT BỊ HÃNG KURABO VIỆT NAM

- THIẾT BỊ CÁC HÃNG

- Thiết Bị đo nhiệt độ Fluke DaTaPaQ

- Thiết Bị Hãng COESFELD

- Thiết bị kiểm tra sản phẫm bằng dung dịch MEK

- Thiết bị Máy đo nhiệt độ tối thiểu hình thành màng sơn MFFT 60

- Thiết Bị Hãng BYK

- Thiết Bị Hãng SHEEN

- Thiết Bị Hãng ELCOMETER

- Thiết bị, Phần mềm kiểm tra độ dày lớp phủ hãng DJH

- Thiết Bị Hãng GARDNER

- Thiết bị máy tạo phản ứng COD hãng WTW , YSI a xylem brand , Fisher scientific model CR4200 COD

- Máy quang phổ tử ngoại/ khả kiến UVVIS - công nghệ tách tia; 190 ~ 1100 nm Model: T60U

- Thiết bị Máy đo độ dày model F0017 cho các sản phẩm

- Dụng cụ sàn rây độ min các loại sơn bột tĩnh điện, sơn nước , bột các loại hãng tyler, Retsch

- Thiết bị máy đo độ dày lớp phủ đa năng MiniTest 3100

- Thiết bị máy đo hàm lượng chromium model NEX QC+

- Thiết bị đo độ cứng MITECH MH600 Portable Hardness Tester

- Thiết bị máy đo hàm lượng ferit ( Sắt) trong các mối hàn model FMP30

- Thiết bị máy đo chỉ số khúc xạ dung dịch model VariRef A B C

- THIẾT BỊ ĐO ĐỘ CỨNG XÁCH TAY MODEL METALTEST HÃNG AFFRI

- HÃNG RIGAKU VIỆT NAM MODEL NEX QC

- Thiết bị kiểm tra nhiệt độ trong lò sấy , lò nung , các loại lò ngành thép luyện kim, gốm sứ , ô tô , thực phẫm hãng PhoenixTM (UK)

- HÃNG KURABO VIỆT NAM

- Thiết bị máy kiểm tra độ cứng kim loại Vicker Macro Vickers Hardness Tester - QV-5Z/10Z/30Z/50Z

- Thiết Bị Hãng ERICHSEN

- Thiết bị phân tích hàm lượng titan, photpho các thành phần trong nhựa , kim loại hãng Rigaku model NEX CG EDXRF

- Thiết bị phân tích hàm lượng titan, photpho các thành phần trong nhựa , kim loại hãng Rigaku model Rigaku NEX QC+QuantEZ EDXRF Analyzer

- Thiết bị kiểm tra độ dày lớp phủ bo mạch, sơn , thành phần kim loai bằng tia xray hãng Bowman XRF Plating Measurement Systems - Precisely Measure and Analyze Plating Thickness. Bowman XRF

- Hệ thống tái chế nước đã sử dụng trong các khu công nghiệp , xử lí nước thải , các hóa chất độc hại nhằm tiết kiệm chi phí và bảo vệ môi trường hãng Witmans

- Thiết bị máy phân tích thành phần kim loai các hợp chất lớp phủ các loại nhựa bao bì sắt thép vàng bạc đá hãng Rigaku hãng SpectroLab hãng Brucker hãng hitachi hãng Thermo Fisher Scientific

- Thiết bị phân tách DNA RNA tự động Benchtop device for automated DNA/RNA isolation model QuickGene-Auto12S/QuickGene-Auto24S QuickGene, GenePrepStar

- Thiết bị đo hàm lượng dung dịch chromium Cr Chrome+3/ +6 model Rigaku NEX QC+ EDXRF Analyzer hãng RIGAKU ngành tôn mạ màu , tôn lạnh

- thiết bị máy so sánh màu model MA-5QC Multi-Angle Spectrophotometer giành cho ngành ô tô hãng X-rite xrite

- Hệ thống phân tích định lượng PCR ( qPCR) REAL TIME PCR QuantStudio 6 and 7 Pro Real-Time PCR Systems dùng trong y học , thực phẫm hãng Applied Biosystem , hãng Thermo Fisher Scientific

- Thiết bị kiểm tra hàm lượng oxy trong nước O2-Lumitrode for dissolved oxygen (DO)

- KASON TESTING MACHINE SUPPLIER

- Thiết bị kiểm tra khuếch đại DNA MáyReal Time PCR (qPCR) hãng Aligent hãng Thermofischer Scientific hãng Biocompare

- Máy chuẩn độ Karl Fischer dùng để phân tích ham lượng nước trong mẫu Model: V20S

- Thiết bị hãng Yasuda testing limits ngành bao bì , vải , cao su , màn film , mực in , sơn các loại hãng YASUDA VIỆT NAM

- Thiết bị cảnh báo nguy hiểm trong các nhà máy , cơ sở sản xuất , các công việc nguy hiểm hãng Pilz GmbH & Co xuất xứ Đức

- Thiết bị chuẩn bị mẫu thử trong phòng thí nghiệm hãng SPEX SamplePrep model 1600 MiniG® - Automated Tissue Homogenizer and Cell Lyser , 5120 Mixer/Mill® - Mini Mixer/Mill® , 8000D Mixer/Mill® - Dual High-Energy Ball Mill, 8530 Sh

- Thiết bị súng cầm tay kiểm tra hàm lượng kim loại model KT-100S hãng Rigaku HANDHELD LIBS METAL ALLOY ANALYZER

- Bạc đạn NSK các loại 6200 , 6202 bearing NSK Bearing 22312 Spherical Roller Bearing 22312 Roller Bearing Deep Groove Ball Bearing 6412 open 60x150x35 mm

- Tủ an toàn sinh học loại II loại A2 Biological Safety Cabinet Class II Type A2

- Thiết bị hãng JSR các loại Autoclave / Steam Sterilizer , Dry Heat Sterilizer Block Heater Centrifuge Digital Hotplate Magnetic Stirrer Digital Homogenizer Forced Convection Oven Bio-Suction Pump 3D Rocker Heated Digital Water Bath Cold Lab C

- Thiết bị kiểm tra nhiệt độ luồng không khí Model 471B Thermo-Anemometer Test Instrument

- Tủ so sánh màu hãng VeriVide Colour Assessment Cabinets Model CAC 60-4 CAC 60-5 CAC 120-4 and CAC 120-5 CAC 150-4 and CAC 150-5

- THIẾT BỊ ĐỌC MÃ VẠCH CẦM TAY BT-W250G HÃNG KEYENCE

- Thiết bị đóng gói bao bì, thực phẫm, máy dò kim loại , cân định lượng sản xuất hãng ishida model QX-1100 Flex Ultimate Performance - IX-G2 Series Carton-Line Tray Denesting Ishida Flexible (F-SPA) and Portable (P-SPA) Str

- Thiết bị hãng Eaton Bộ chuyển đổi tần số Eaton PowerXL DM1 mới: kích thước nhỏ hơn và hiệu suất tuyệt vời

- Thiết bị kiểm tra độ kéo căng tensil hãng Lloyd model LS5 tester LS Series - Up to 5 kN 5 kN / 1124 lbf Advanced Material Testing System LS5

- Thiết bị hệ thống máy đo phân tích sắc kí lỏng model UltiMate 3000 HPLC and UHPLC systems HPLC - High Performance Liquid Chromatography

- Thiết bị bộ đếm hạt di động giành cho các hạt dung dịch chất lỏng HIAC PODS + bộ đếm hạt chất lỏng HIAC PODS+ Portable Liquid Particle Counter hãng Beckman hãng CLEANEARTH HIAC 8011+ Liquid Particle Counting Syste

- Tủ phun muối model BND/60(108) model BND/90(220)

- Đầu dò đo nhiệt độ trong lò ngành sơn tĩnh điện , ngành nhôm các hãng Phoenixtm hãng datapaq hãng fluke hãng elcometer

- Thiết bị đo độ dày sơn Model FTS-DJH 2021(New) KOREA

- Thiết bị máy phân tích khí đốt và khí thải công nghiệp như O2, CO, NO, NO2, SO2, CxHy model E4500 model E1500 model E6000 model E8500 model E9000 hãng Sauermann hãng EInstruments

- Máy kiểm tra độ rung của vòng bi HS-620 Compact & Portable Vibration Meter

- Thiết bị kiểm tra độ dày, độ ẩm bao bì nhựa trong sản xuất bao bì, cán màng , các tấm film quang học Optical film hãng Kurabo model RX-1000 và model rx-2000

- Thiết bị kiểm tra Covid hãng PixoTest® POCT COVID-19 Antigen Testing Việt Nam

- Thiết bị máy phân tách sắc khí model G5 Gas Chromatograph Canada

- Thiết bị đo độ cứng Shore HPE II hãng Bareiss xuất xứ Đức

- BẢNG SO SÁNH MÀU MẪU

- COATING DRILL VIỆT NAM

- TỦ SẤY CÁC HÃNG

- HÃNG DEFELSKO thiết bị hãng Defelsko

- GIẤY KÉO HÃNG LENETA

- MÁY CHÂN CẤT NƯỚC

- THIẾT BỊ ĐO ĐỘ NHỚT

- CÂN ĐIỆN TỬ CHÍNH HÃNG

- MÁY ĐO ĐỘ DÀY ANTIFINGER KURABO

- THIẾT BỊ HÃNG T-MACHINE

- Thiết bị tủ phun muối T - MACHINE

- Thiết Bị Tuần hoàn T-Machine

- Thiết bị tạo thời tiết T-MaChine

- Thiết Bị kiểm tra độ sốc nhiệt T-Machine

- Thiết Bị Phòng Nhiệt Độ & Độ Ẩm Có Thể Lập Trình

- Thiết Bị Buồng Dốc Nhiệt Độ Có Thể Lập Trình

- Thiết Bị Buồng Nhiệt Độ & Ấp Suất Thấp

- Thiết Bị Phòng Kiểm Tra Độ Ẩm

- Thiết Bị Phòng Thử Nghiệm Bụi

- Thiết Bị Máy Đo Chấn Động Đèn Ô Tô

- Thiết Bị Phòng Ngâm Nhẹ

- Thiết Bị Phòng Thử Nghiệm Môi Trường Hỗn Hợp

- Thiết Bị Đo Độ Tụ Của Đèn Xe Hơi

- Lò Kiểm Tra Độ Lão Hóa Nhiệt Của Chất Dẻo, Vật Liệu Cách Điện

- Thiết Bị Máy Kiểm Tra Lão Hóa Ozone

Hỗ Trợ Trực Tuyến

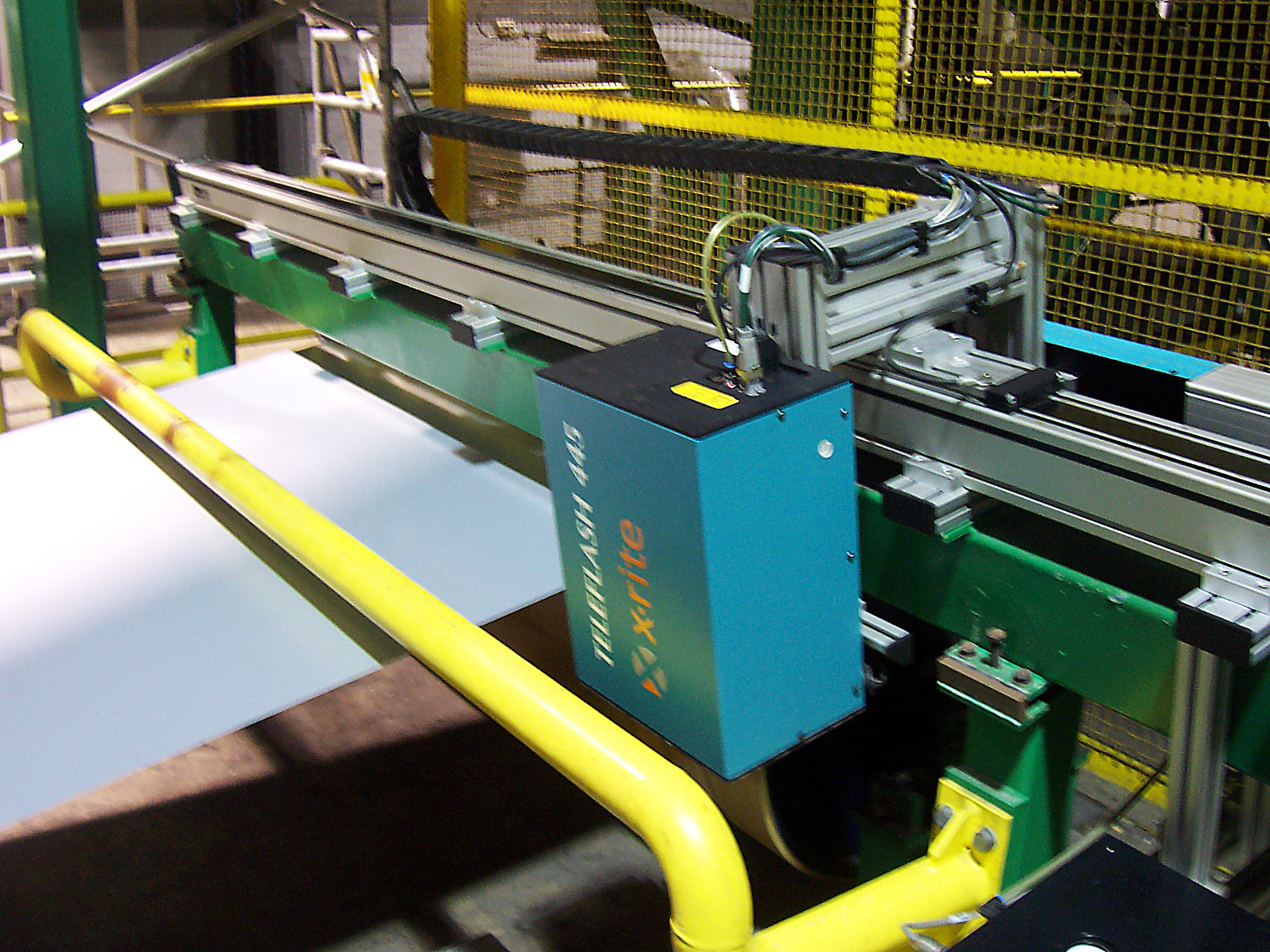

Máy So Sánh Màu Quang Phổ Ngành Tôn Thép

Recently, we published an article about measuring color inline. Coil coating is one area where inline color measurement is very effective for achieving the most cost benefit by focusing on speed, quality, and accuracy.

The coil coating process has been around for more than 30 years, allowing companies to produce durable and attractive products. However, to achieve cost benefit, the focus must be on speed, quality and accuracy. Coil coating gives manufacturers a way to paint the metal while it is still in sheet form. This is important, because trying to paint metal after it has been formed into parts makes it difficult to achieve a uniform coating.

The coil coating process is fast, and mistakes must be caught immediately to avoid expensive waste. X-Rite’s Coil Coating Inline Color Measurement System incorporates the ERX50 or the TeleFlash® 445 Inline Spectrophotometer and the GlossFlash 6060 Inline Gloss Meter to help manufacturers ensure color and gloss quality and consistency, real-time, during each step of the process.

Today we’ll explore the coil coating process and learn how an inline system can help achieve quality and accuracy.

Heat can affect color consistency. The sheet is cured in an oven at least twice during the coating process, and the time spent in the oven combined with variations in oven temperature can impact color.

Paint variations can cause metamerism, where the color looks right under one type of lighting, but changes under a different lighting condition.

The gloss of the paint will affect the appearance of the color, making it look lighter or darker.

Variations in the paint thickness will also affect the color. The coating must be consistent throughout the entire process to achieve uniformity.

Add to that the fast pace of the production line, and you can see why it’s a challenge for coil coaters to meet vigorous color standards.

A five-step solution for controlling color

X-Rite has developed an inline system to monitor the entire coil coating process. Using the ERX50 Inline System or the TeleFlash 445 Inline Spectrophotometer together with the GlossFlash 6060 Gloss Meter, manufacturers can measure color and gloss with a high degree of accuracy during each step – in the lab, on the production line, and through final quality control reporting and documentation.

The coil coating process

The coil coating process is fast… with coil strips moving up to 700 feet per minute! Each step is critical to producing superior color quality and coating consistency. Here’s how it works.

- The coil strip is unwound, cleaned, and brushed.

- A chemical treatment is applied, and the strip is dried.

- A primer is applied to one or both sides of the strip.

- The strip is then cured in an oven, removed and cooled.

- The coating is applied to one or both sides of the strip.

- The strip passes through a second curing oven and is cooled.

- Finally, the coated coil is rewound.

What can go wrong? A lot.

Specifications

| Short Term Repeatability - White | < 0.03 dE(CMC) |

|---|---|

| Measurement Geometry | 45°/0° |

| Measurement Time | Flash |

| Measurement Working Distance | 55mm |

| Spectral Interval | 400-700nm |

| Spectral Range | 20nm0.1 |

0976.299.749

0976.299.749

Tổng truy cập:

Tổng truy cập: