Thiết bị kiểm tra chất lượng, khuyết tật, hư hại của bao bì lon Beverage cans Beverage Can Buckling/Seam Inspection hãng Kurabo Việt Nam

Beverage Can Buckling/Seam Inspection

For customers troubled by a can’s thin wall, with buckling, dents, or seaming failures caused by a wide variety of cans!

Features

Compact design

KURABO’s compact inspection system does not require a wide space or major production line changes.

Unique inspection method

Enables whole sidewall inspection by detecting distortion of light lines projected onto the sidewall of the can.

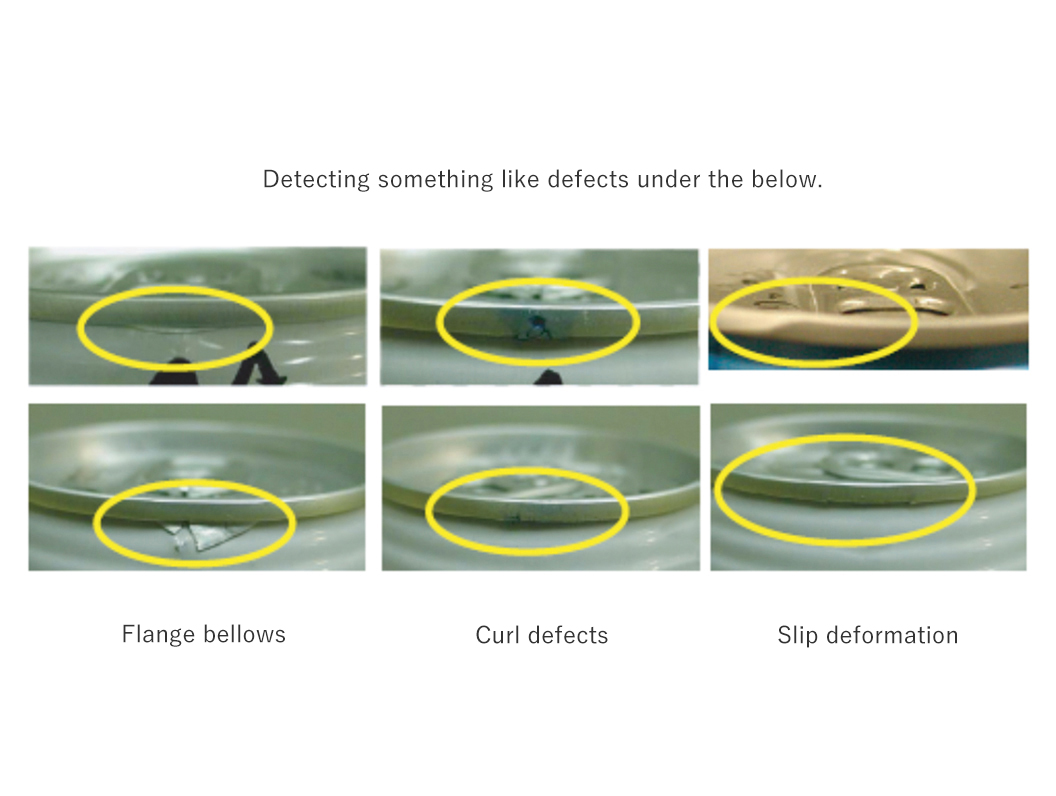

Prevents serious customer complaints such as leakage caused by buckling or seam defects of the can.

Inspection data feedback, especially saved images of defects, helps to identify the cause of defects.

Single camera system

KURABO’s Seam Defects Inspection System monitors the thickness of the seam with a single camera. When it becomes wider, the can will be rejected from the production line.

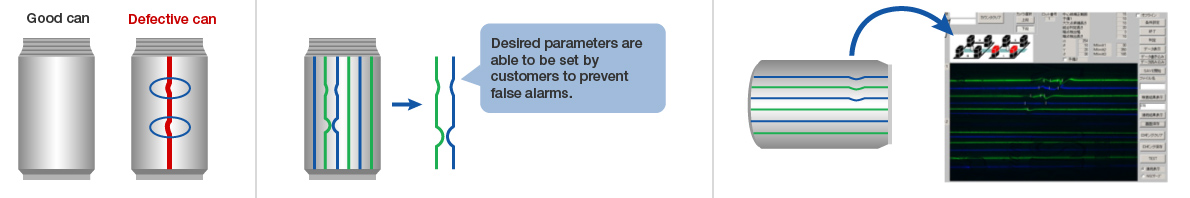

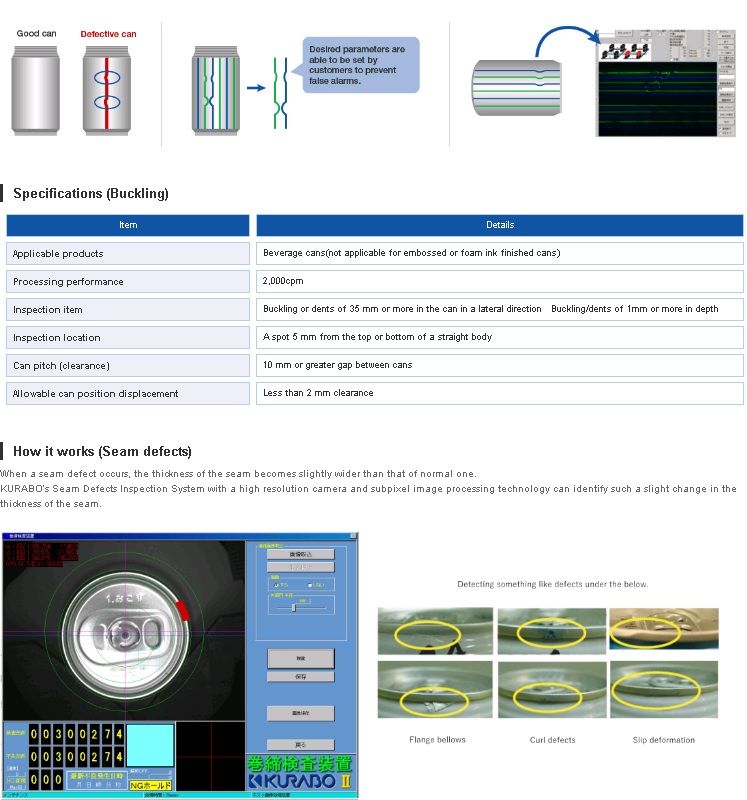

How it works (Buckling)

While projected light lines onto the sidewall of a good can will never be distorted, those of a can with buckling or seam defects will be.

KURABO’s image processing technology accumulated over many years of R&D enables this distortion to be detected without being affected by water drops on the surface of the can, and as a result, increases production yield.

Specifications (Buckling)

| Item | Details |

| Applicable products | Beverage cans(not applicable for embossed or foam ink finished cans) |

|---|---|

| Processing performance | 2,000cpm |

| Inspection item | Buckling or dents of 35 mm or more in the can in a lateral direction Buckling/dents of 1mm or more in depth |

| Inspection location | A spot 5 mm from the top or bottom of a straight body |

| Can pitch (clearance) | 10 mm or greater gap between cans |

| Allowable can position displacement | Less than 2 mm clearance |

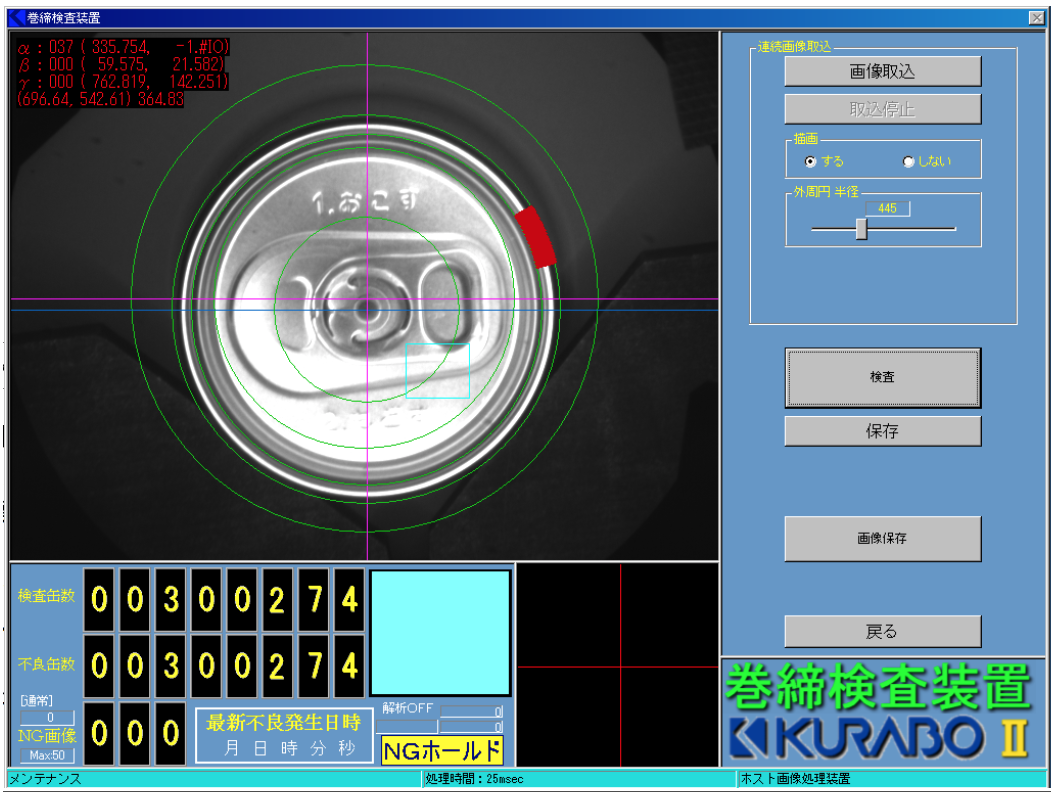

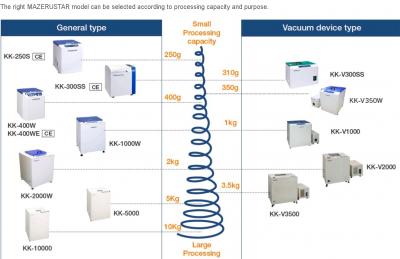

How it works (Seam defects)

When a seam defect occurs, the thickness of the seam becomes slightly wider than that of normal one.

KURABO’s Seam Defects Inspection System with a high resolution camera and subpixel image processing technology can identify such a slight change in the thickness of the seam.

Specifications (Seam defects)

| Item | Details |

| Applicable products | Beverage cans |

|---|---|

| Processing performance | 20,000cpm |

| Inspection item | Seam defects |

| Allowable can position displacement | Less than 2 mm clearance |

0976.299.749

0976.299.749

Tổng truy cập:

Tổng truy cập: